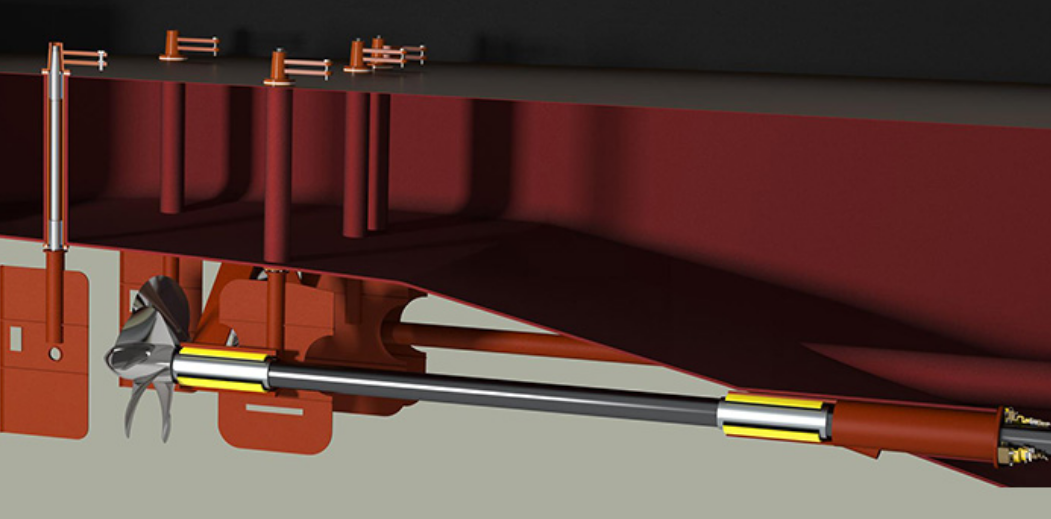

Thordon Bearings RiverTough system

Thordon Bearings Inc. says that demand for environmentally sustainable water-lubricated and grease-free bearings and seals has increased dramatically in the U.S. and Latin American inland waterways market as more and more operators look to renew their fleets in line with environmental rules and regulations. The company reports that it has seen a large increase in orders for its water-lubricated RiverTough tailshaft bearings over the past three years. Orders for the company’s grease-free, self-lubricating ThorPlas Blue bearings, TG100 shaft seals, and pucker seals have also seen similar growth.

Speaking during the International Workboat Show, in New Orleans, Jason Perry, Thordon’s regional manager, North America, said: “With much of the inland waterways fleet in the Americas comprised of relatively old vessels, environmental upgrades make good sense. And with waterborne freight on the increase, a whole new generation of more sustainable workboats is set to expand the fleet as environmental priorities and ESG issues in inland waterway operations climb the agenda. Owners are embracing the environmental and commercial benefits Thordon can bring to inland waterway operations.”

“Our workboat solutions not only meet the environmental targets set by vessel owners, but they are also popular with shipyards since the bearing material is much easier to machine and faster to fit than traditional rubber and greased bronze solutions,” added Perry. “A Thordon system reduces the operational and maintenance spend, improves system reliability, and removes the oil and grease-free interface between vessel and water.”

While market demand for Thordon products in the U.S. is significant, Latin America is theregion where Thordon has registered its largest growth in the inland waterways sector over the past three years.

“We have seen a marked increase in interest for more environmentally safe solutions across the Americas, particularly for RiverTough bearings and TG100 seals, as the sector looks to renew its fleet with more efficient solutions,” said Scott Groves, vice president, sales at Thordon Bearings. “We have been able to meet this market demand by investing in new warehousing and inventory capability. We have established a robust supply chain so that all products are available at key locations across the inland waterway network, whenever and wherever our customers require them. And that is a key selling point for inland waterways operators for whom any delay or downtime is a costly exercise.”

(https://www.marinelog.com)

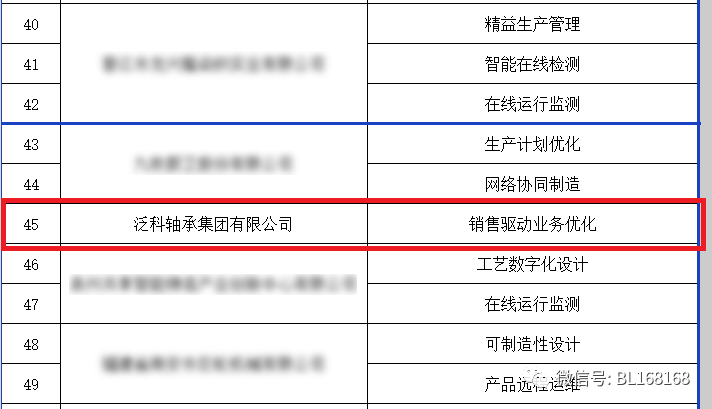

More About FK:

FK Bearing Group Co.,Ltd. was orignally founded in 1969 and always focuses on Bearing Units in the past 50 years. FK has complete industrial chain automatic factory of its own, now FK is one of the biggest bearing parts factories in China with annal production and sales up to 18 million pieces.

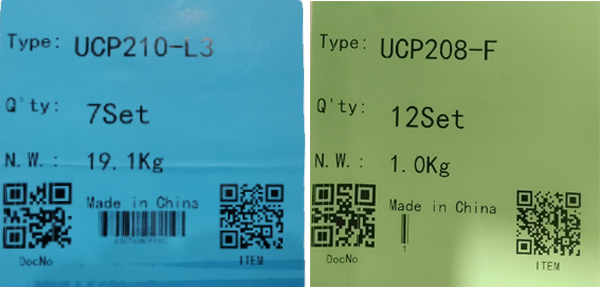

2022 New Week Hot Products Recommended:

An air handler, or air handling unit (often abbreviated to AHU), is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. In Fanke, Air Handling Bearing Units include many types. FK Group warmly welcome you to buy top quality air handling bearing units.

https://www.fk-bearing.com/products/Air-Handling-Bearing-Units/870.html

More Products please do not hesitate to view here:

https://www.fk-bearing.com/products/catalogue.html

For dimensions and specifications, contact us now.

TEL: 86-595-86396027

FAX: 86-595-86382510

E-mail: export@fk-bearing.com

Website: www.fk-bearing.com

Mobile: m.fk-bearing.com

English

English Spanish

Spanish French

French German

German Portugal

Portugal Italy

Italy Korean

Korean Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish Arabic

Arabic Russian

Russian Czech

Czech Thai

Thai Irish

Irish Bulgarian

Bulgarian Poland

Poland Croatian

Croatian Ukrainian

Ukrainian Bosnian

Bosnian Lithuanian

Lithuanian Latvian

Latvian Romanian

Romanian Greek

Greek Danish

Danish Hungary

Hungary Norwegian

Norwegian Finnish

Finnish Dutch

Dutch Swedish

Swedish Slovak

Slovak Slovenian

Slovenian Indonesian

Indonesian Bengali

Bengali Serbian

Serbian Uzbek

Uzbek